What is

TIG welding?

TIG welding: clean seams, stable connections

TIG welding: This is how it works

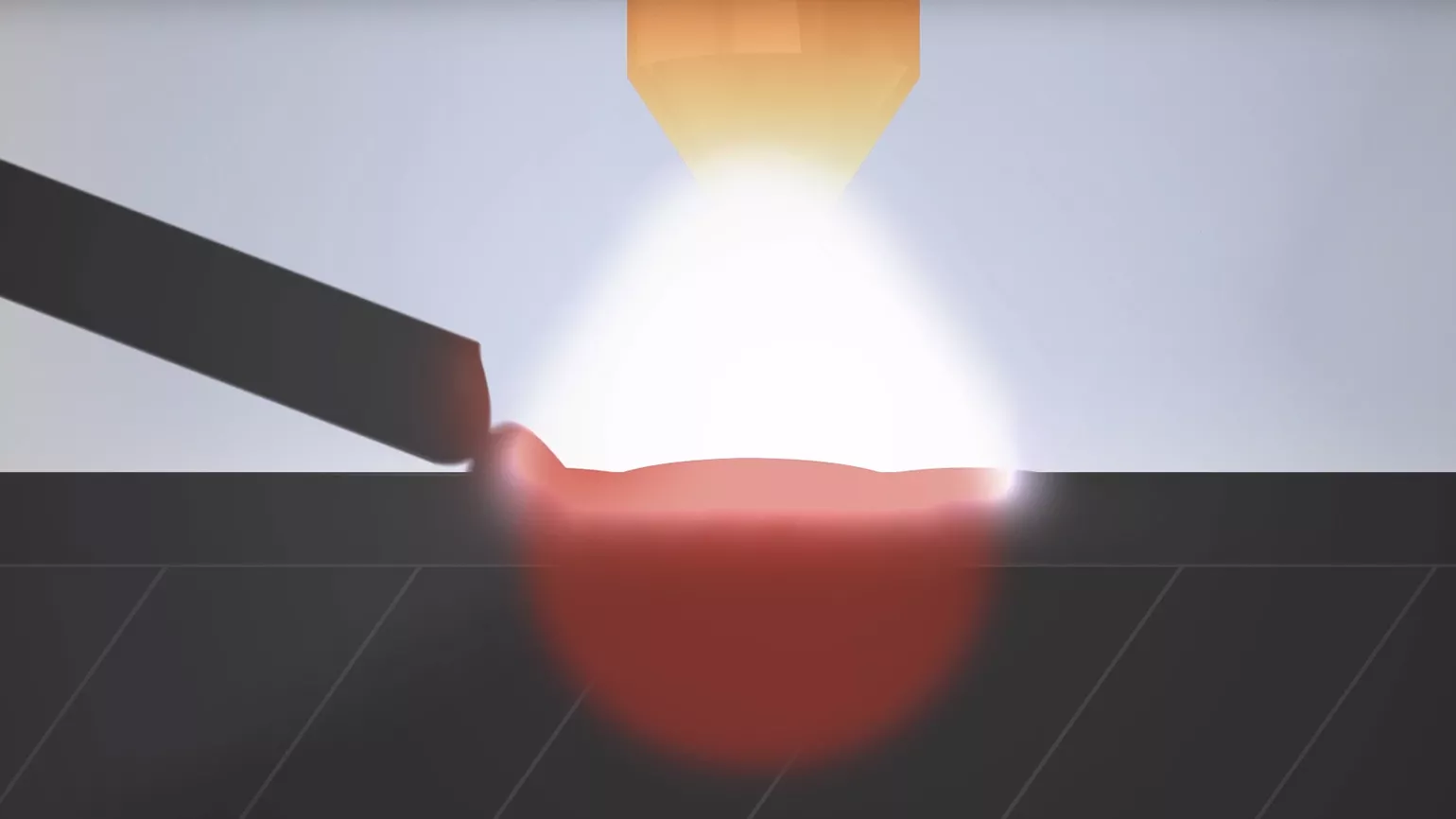

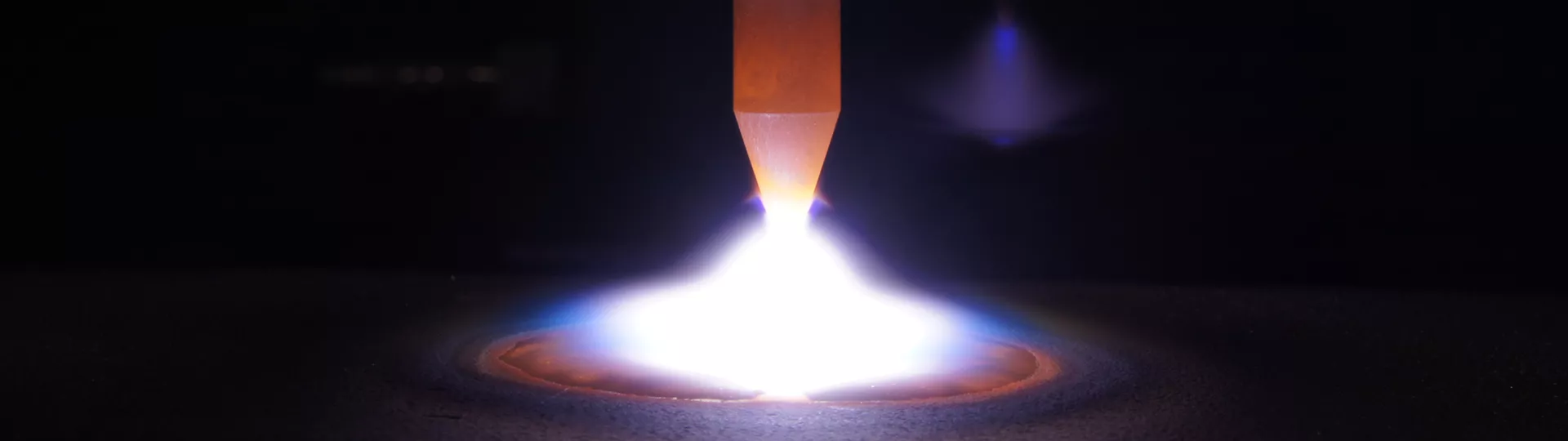

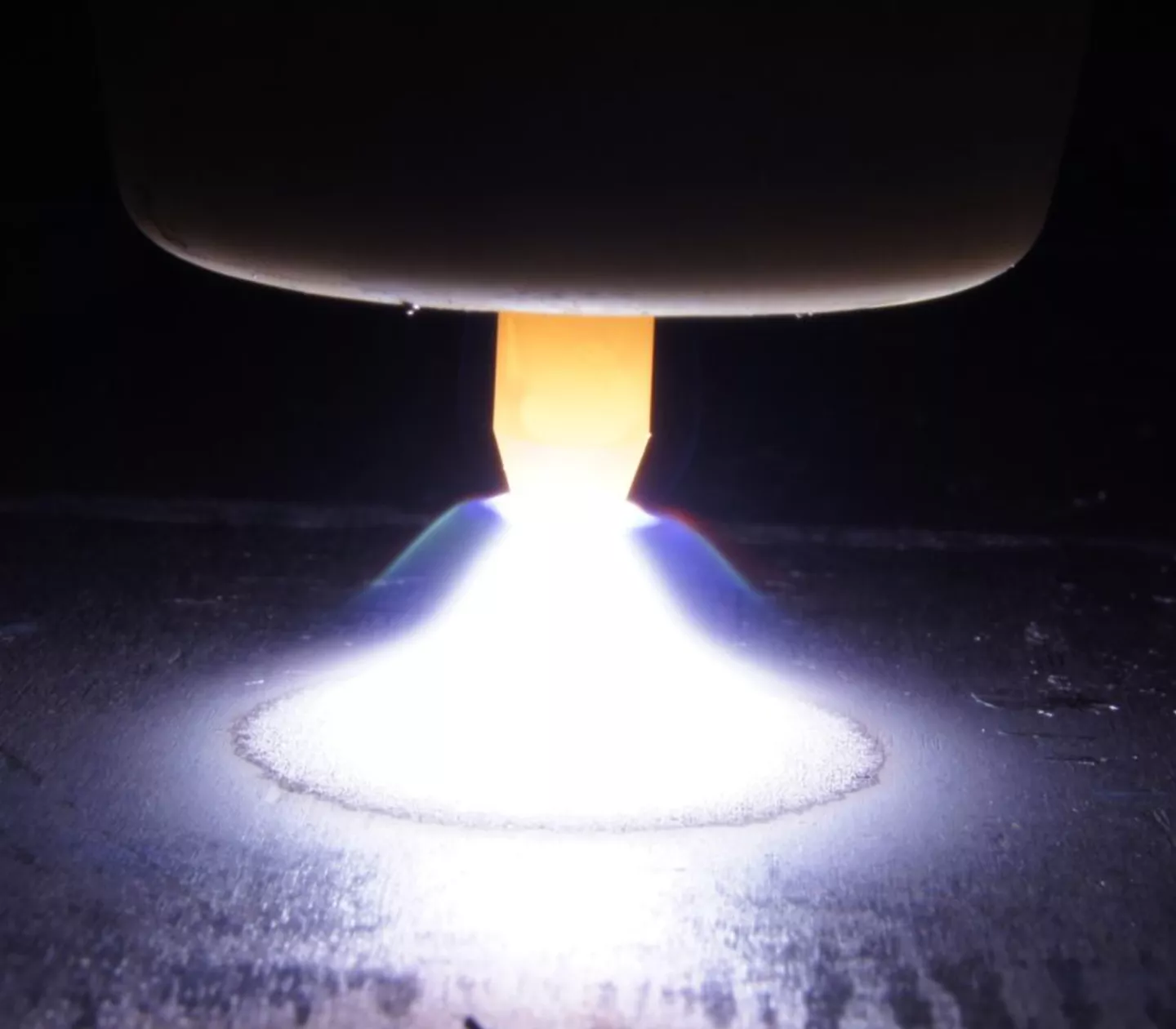

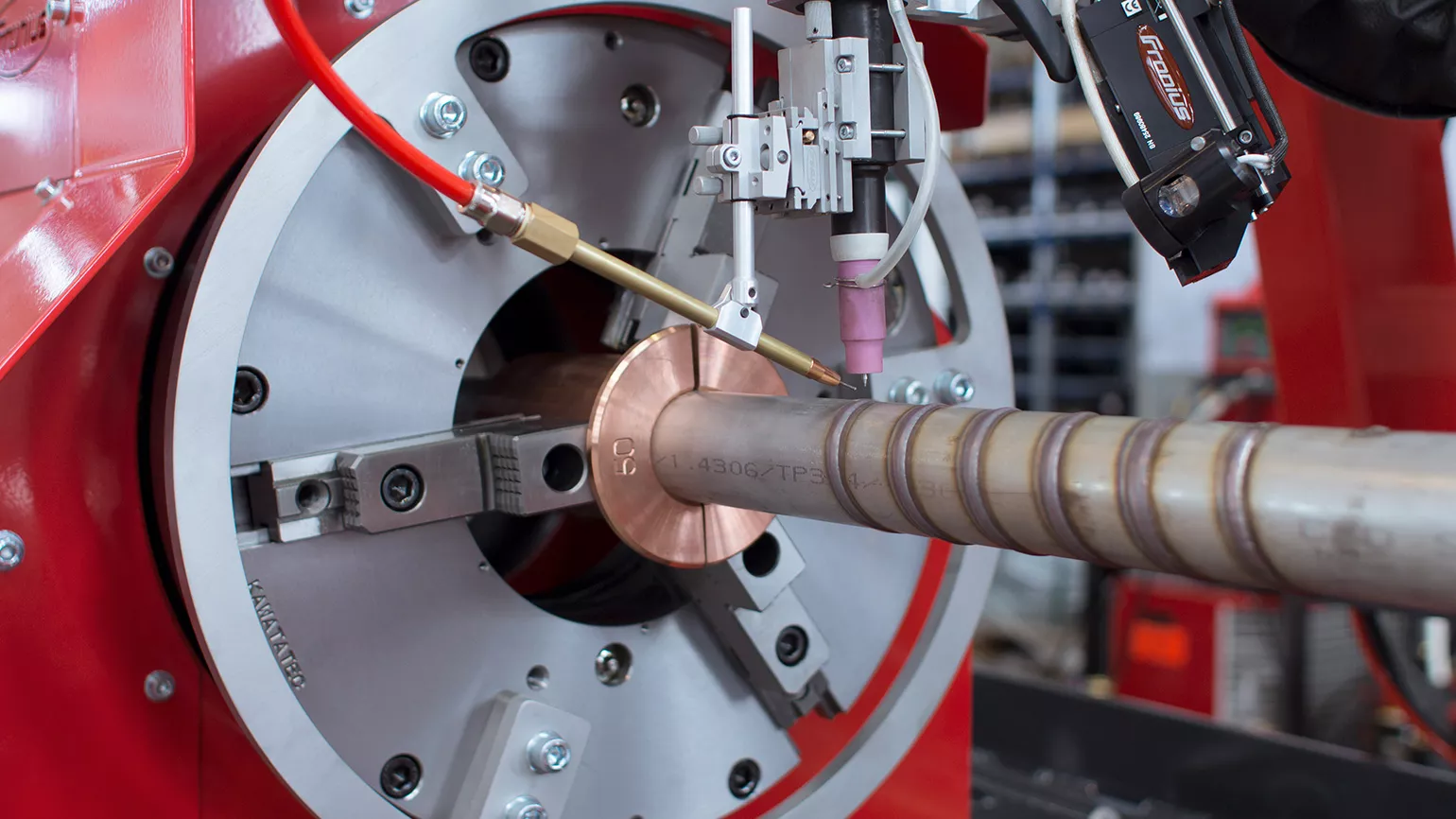

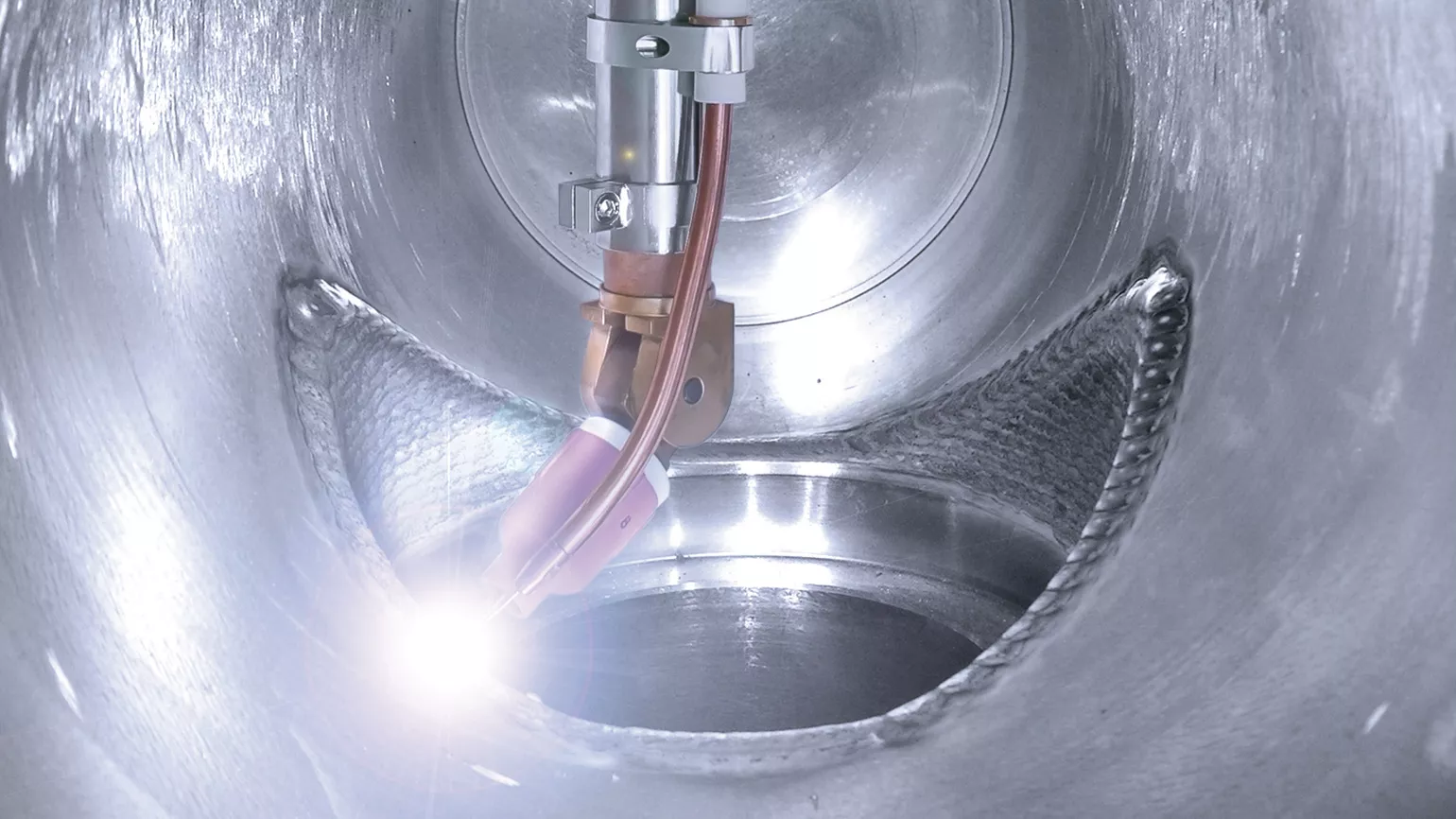

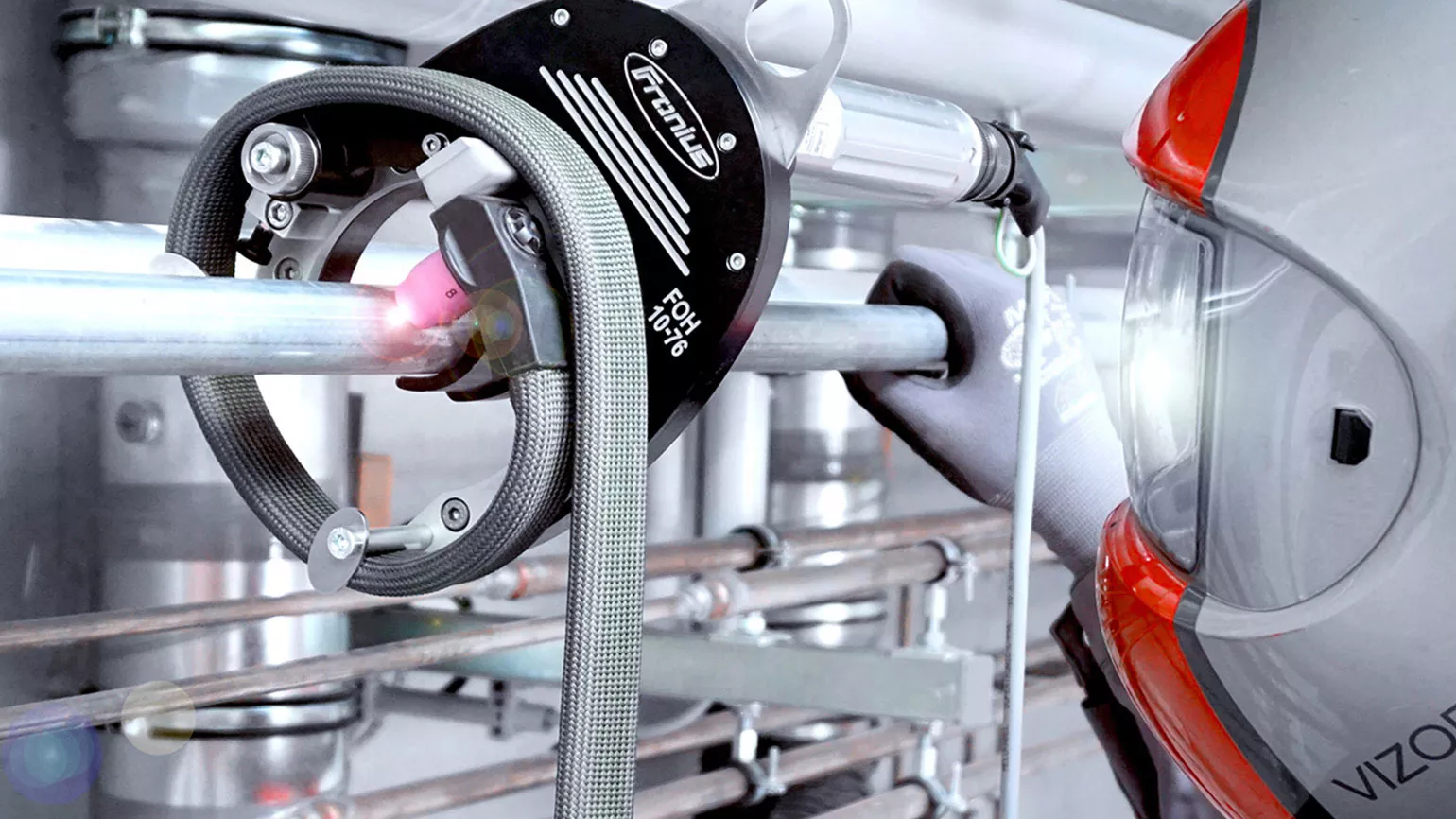

In TIG welding, the required current is supplied via a tungsten electrode, which is temperature-resistant and does not melt. This electrode emits an arc that heats up and liquefies the material. There is a nozzle for shielding gas around the electrode. This protects the heated material from chemical reactions with the ambient air. The noble gases argon, helium or mixtures thereof are used for this purpose. The inert, i.e. non-reactive, gases prevent chemical reactions with the liquid weld pool and the heated material. This ensures high-quality weld seams.

As the tungsten electrode does not melt, in TIG welding the filler material is fed in by hand or in mechanized form by an external wirefeeder.

The tungsten electrode

This is how a TIG welding system is structured:

(1) Mains connection

(2) Power source

(3) Hosepack

(4) Grounding cable

(5) Welding torch

(6) Ground terminal

(7) Workpiece

(8) Filler metal

(9) Shielding gas

Process variants of TIG welding

Which materials are suitable for TIG welding?